Подтверждено Минпромторгом России

Подтверждено Минпромторгом России

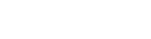

AFU-8

Фильтро-вентиляционная установка

Фильтровентиляционная установка AFU-8 предназначена для очистки воздуха от взвешенной, мелко- и среднедисперсной пыли и дыма, выделяющихся во время сварки, пайки, термической резки металлов и прочих процессов. AFU-8 может использоваться для решения проблем с загрязнением воздуха в производственных помещениях, или как элемент технологического процесса: в любом случае двухступенчатая очистка обеспечит высокоэффективное, непрерывное и оперативное удаление пыли и дыма.

ФВУ AFU-8 осуществляет замкнутый цикл циркуляции воздуха, что позволяет сохранять тепло в производственном помещении.

Станки "Юнимаш" изготавливаются на предприятии в Санкт-Петербурге из комплектующих собственного производства. Имеется Заключение Минпромторга о подтверждении производства на территории РФ.

| Технические характеристики | |

|---|---|

| Масса, кг | 1700 |

| Присоединительный фланец | ∅ 355 мм |

| Производительность | 8000 м3/час |

| Давление воздуха | 5-7 атм. |

| Расход воздуха | не более 60 л/мин (только в цикле регенерации фильтров) |

| Напряжение питания | 380 VAC, 50 Hz |

| Потребляемая мощность | не более 7,6 кВт |

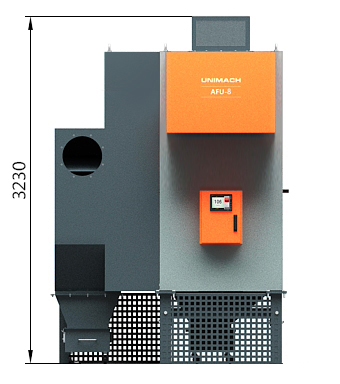

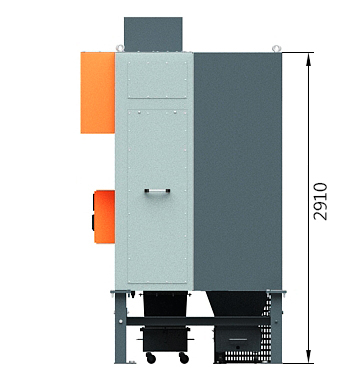

| Габаритные размеры (мм) | ||

|---|---|---|

| Ширина | 2130 | |

| Высота | 3230 | |

| Глубина | 1845 | |

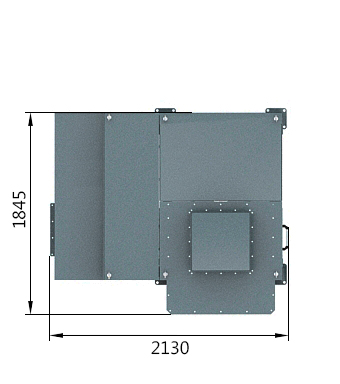

Габаритные размеры установки

Рис. 1 - Габаритные размеры AFU-8

Преимущества AFU-8

- Фильтрующие элементы специальной формы, увеличивающие общую производительность системы и срок службы самого фильтра

- Фильтр-циклон предварительной очистки, удаляющий основную часть загрязнения, что значительно увеличивает срок службы фильтрующих элементов

- Низкий уровень шума при высокой производительности системы

- Инверторное цифровое управление. Инверторное управление обеспечивает плавный старт, плавную регулировку мощности всасывания с высоким КПД

- Электронный контроллер. Контроллер ФВУ производит интеллектуальный замер загрязнённости фильтрующих элементов, и, при необходимости, запускает процесс очистки. Это значительно увеличивает срок службы фильтрующих элементов

- Экономия электроэнергии. Инверторное управление с «умным» контролем мощности обеспечивает снижение энергопотребления, в том числе, за счёт перехода в «ждущий режим» когда нет необходимости в работе установки на полную мощность

- Графический дисплей обладает интуитивно понятным интерфейсом с удобной индикацией рабочих параметров и сообщений системы

- Гарантия 2 года