Лазерная оптическая головка LH

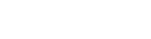

LH-201

Лазерная оптическая головка LH 201 – высокотехнологичное решение для станков лазерного раскроя металла. Особое внимание при разработке новой инновационной серии головок уделялось усовершенствованию конструкции, увеличению стабильности температурных характеристик линз, внедрению систем и датчиков контроля состояния элементов оптической головки.

Компактная и облегченная конструкция позволяет достигать максимальной эффективности при движении оптической головки. Эффективная система охлаждения предоставляет возможность работы с лазерным излучением высокой мощности. Принудительное воздушное охлаждение сопла препятствует его перегреву во время резки, помимо этого добавлено дополнительное водяное охлаждение сопловой части.

Особое внимание при разработке данной серии оптических головок уделялось поддержке мощных излучателей. Продуманная система охлаждения внутренних оптических модулей, повышенная герметичность корпуса в купе с новой оптической системой, установленные датчиками контроля за оптикой, индикация состояния отдельных узлов позволяют использовать лазерную оптическую головку 24/7 на больших мощностях на промышленных предприятиях страны.

Удобная индикация в нижней части модуля позволяет быстро оценить текущее состояние головки и своевременно предотвратить аварию, а системы защита от столкновений позволяет предотвратить контакт оптической головки со вставшей деталью в процессе холостых перемещений.

Преимущества лазерной оптической головки LH-201

- Система защиты от столкновений

- Комплекс дополнительных систем контроля и датчиков работы оптической головки

- Картриджная замена защитного стекла

- Температурный контроль сопла

- Охлаждение и обдув сопла. Дополнительно водяное охлаждение сопловой части

- Встроенная система автоматического слежения за поверхностью листа FoCut

- Коллиматор с прецизионным контролем точки фокуса

- Высокая чувствительность датчиков FoCut и защиты от боковых столкновений

- Светодиодная индикация состояния оптической головки

- Автоматическая регулировка фокусного расстояния

- Водяное охлаждение оптики

- Защитное стекло расположено на значительном расстоянии от сопла

Оптическая головка LH-201

Система защиты от столкновений

Система защиты от столкновений определяет потенциально опасные участки (поднятые над листом детали, прижимы листа, не внесённые в зону безопасности и пр.) в режиме реального времени. При обнаружении препятствия оптическая головка поднимается и переходит опасный участок или останавливает процесс обработки листа.

Комплекс дополнительных систем контроля и датчиков работы оптической головки

Для качественного реза и надежной работы с излучателями высокой мощности, новая оптическая головка LH-201 снабжена большим количеством дополнительных датчиков, которые позволяют контролировать и оценивать текущую работу станка. Среди прочих, комплекс содержит следующие системы:

- Камера контроля температуры и уровня загрязнения фокусирующей линзы;

- Камера контроля температуры и уровня загрязнения коллиматора;

- Камера контроля температуры и уровня загрязнения защитного стекла;

- Датчик температуры и влажности воздуха в камере;

- Датчик давления в рабочей камере;

- Датчик загрязненности воздуха в верхней камере;

- Датчик наличия установленного защитного стекла;

- Датчик утечки рабочего газа в зону оптики.

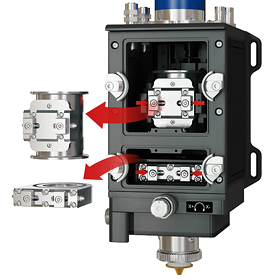

Картриджная замена защитного стекла

Защитное стекло, закрывающее фокусирующую линзу, может периодически нуждаться в замене. Для упрощения процесса замены предусмотрен картридж с удобной системой ручной фиксации без использования инструмента.

Конструкция картриджа позволяет легко извлечь его из оптической головки. После замены стекла он так же легко вставляется обратно, надёжно защищая оптическую систему от внешних воздействий. Использование картриджа существенно ускоряет и облегчает обслуживание оптической головки.

Фокусирующие линзы и коллиматорная защита также устанавливаются на картриджах и при возникновении сервисной необходимости могут быть заменены с минимальными затратами времени и сил.

Температурный контроль сопла

Неправильная юстировка излучения относительно центра сопла приводит к его сильному нагреву вплоть до расплавления, ухудшает качество резки и может привести к выходу из строя оптической головки. Встроенный датчик реагирует на повышение температуры сопла, в результате чего на операторской стойке выдаётся ошибка и станок приостанавливает работу. Функция актуальна также при резке цветных металлов и оцинкованной стали.

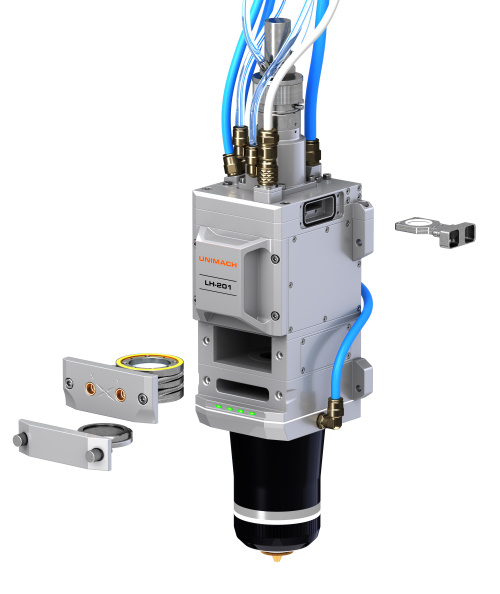

Охлаждение и обдув сопла. Дополнительно водяное охлаждение сопловой части

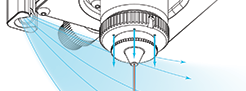

Чтобы не допустить перегрева сопла с его последующей деформацией, используют системы охлаждения. Сопловую насадку оснащают отверстиями, через которые под давлением подаётся воздух. Обдувая сопло, воздушные потоки препятствуют росту его температуры.

При работе с металлами, обладающими высокой отражающей способностью, воздушного охлаждения может оказаться недостаточно. На этот случай предусмотрено дополнительное водяное охлаждение. Проходя по каналам в нижней части оптической головки, вода снимает тепловую нагрузку. Температура сопла понижается.

Система FoCut

Встроенная система автоматического слежения за поверхностью листа FoCut является наиболее производительной из аналогичных систем, представленных на рынке. FoCut обеспечивает стабильность удержания оптической головки с точностью до 0,05 мм в широком диапазоне высот, что позволяет четко работать даже на сильно деформированном металле, а также на краях заготовки.

Коллиматор с прецизионным контролем точки фокуса

Благодаря наличию привода блока перемещения коллимирующих линз изменение точки фокуса происходит практически мгновенно согласно выбранному режиму резки. Вкупе с многоэтапным прожигом металла это позволяет производить стабильно качественную пробивку и обработку металла. Использование прямой системы измерения положения коллимирующего блока позволяет держать точку фокуса с прецизионной точностью. Наличие асферической оптики позволяет добиться наилучшего качества реза.

Увеличенная чувствительность датчиков

В новой оптической головке LH-201 были переработаны и улучшены датчики слежения за зазором и защиты от боковых столкновений. Датчик слежения за зазором системы FoCut теперь работает до высоты в 70мм, а датчик защиты от боковых столкновений определяет вставшие заготовки на расстоянии в 2 раза большем, чем на предыдущих моделях оптических головок.

Светодиодная индикация состояния оптической головки

Удобная светодиодная индикация на оптической головке позволяет быстро оценить её текущее состояние и своевременно предотвратить аварию. Индикаторы состояния информируют оператора о режимах температуры и давления, уровне загрязнения линз и защитного стекла, статусах работы системы.

Автоматическая регулировка фокусного расстояния

Благодаря встроенному приводу линзы, автоматическая регулировка фокусного расстояния не только облегчает настройку режима резания, но и повышает скорость пробивки материала за счет смещения точки фокуса в момент прожига. Подстройка фокусного расстояния происходит автоматически, при выборе материала из библиотеки.

Водяное охлаждение оптики

Благодаря отдельным контурам охлаждения оптического тракта, температура оптической группы всегда имеет оптимальное значение, что исключает запотевание или неравномерный нагрев линз.

Защитное стекло расположено на значительном расстоянии от сопла

Внутреннее расположение элементов в оптической головке LH-201 было изменено таким образом, чтобы значительно увеличить расстояние от сопла до защитного стекла. За счет этого защитное стекло имеет увеличенный ресурс работы и в целом позволяет увеличить производительность станка.

Технические характеристики LH-201

- Диапазон регулировки фокусного расстояния от плюс 15 до минус 35 мм;

- Изменение точки фокуса «на лету» (в том числе при пробивке материала);

- Автоматическое изменение положения линзы при выборе материала из библиотеки;

- Силовой обдув точки врезки при пробивке материала;

- Поддержка линз с фокусным расстоянием 200 мм (опционально 250 и 300мм);

- Электромеханический привод линзы;

- Управление положением линзы с ЧПУ;

- Интегрированный драйвер управления приводом линзы с обратной связью;

- Контроллер Z-координаты подключен по цифровой шине (интегрировано управление оптической головкой и получение данных от встроенных датчиков);

- Центровка сопла в узле фокусатора;

- Многоэтапный прожиг.

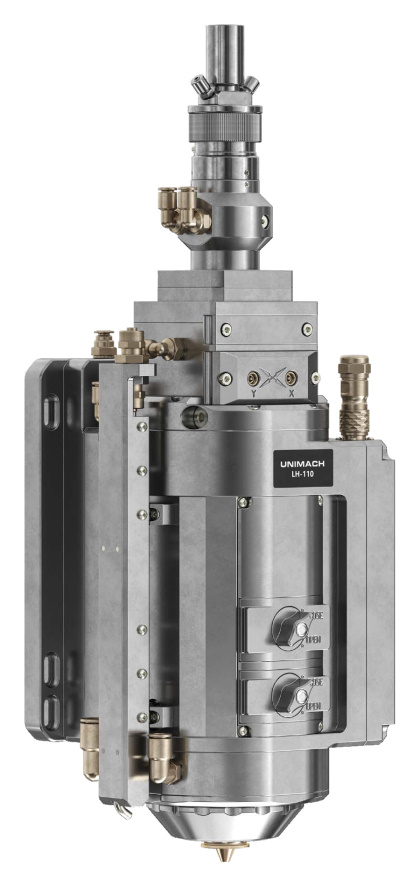

LH-110

Разработанная нами оптическая головка LH‐110 поднимает автоматизацию процесса лазерной резки на совершенно новый уровень. Автоматическая регулировка фокусного расстояния, благодаря встроенному приводу линзы, не только облегчает настройку режима резания, но и повышает скорость пробивки материала за счёт смещения точки фокуса в момент прожига. При выборе материала из библиотеки подстройка фокусного расстояния происходит автоматически.

Картриджная система замены линз и защитных пластин значительно сокращает время обслуживания оптической головки и ускоряет процесс замены фокусирующей линзы. Температурный контроль сопла продлевает ресурс его работы. Коллиматор с регулируемой линзовой системой служит для точной калибровки лазерного излучения, что позволяет работать с бóльшими толщинами, а также добиться наилучшего качества резки и увеличить её скорость.

Улучшенная система охлаждения дает преимущество при работе с излучателями высокой мощности. В обновленной конфигурации оптической головки добавлено водяное охлаждение фокусирующей линзы и второй контур охлаждения коллиматора, а также полностью обновлен контур охлаждения резака. Принудительное воздушное охлаждение препятствует перегреву сопловой части во время резки. Актуально для резки цветных металлов ввиду их высокого коэффициента переотражения.

Существенным преимуществом в новой версии оптической головки является то, что платы управления резаком вынесены в отдельный блок, что способствует соблюдению оптимального температурного режима работы. Дополнительная защита от столкновений определяет потенциально опасные участки (поднятые над листом детали, прижимы листа, не внесённые в зону безопасности и пр.) в режиме реального времени. При обнаружении препятствия оптическая головка поднимается и переходит опасный участок или встаёт на паузу.

Технические характеристики LH-110

- Система защиты от столкновений;

- Электромеханический привод линзы;

- Автоматическое изменение положения линзы при выборе материала из библиотеки;

- Водяное охлаждение оптики;

- Управление фокусным расстоянием из ЧПУ;

- Силовой обдув точки врезки при пробивке материала;

- Интегрированный датчик системы слежения FoCut;

- Быстрая (картриджная) замена фокусирующей линзы;

- Быстрая (картриджная) замена защитной пластины;

- Автоматическое выставление фокуса при выборе материала из библиотеки;

- Диапазон регулировки фокусного расстояния: 40мм;

- Изменение положения линзы (точки фокуса) «на лету» (в том числе при прожиге материала);

- Юстировка излучения относительно центра сопла при помощи коллиматора;

- Обдув защитной пластины;

- Охлаждение зоны резания;

- Датчик температуры сопла;

- Охлаждение сопла;

- Интегрированные приводы управления приводом линзы;

- Увеличенная чувствительность датчиков (боковое слежение – в 2 раза, системы FoCut – до высоты 50 мм);

- Коллиматор с регулировкой фокусного положения линз;

- Диапазон регулировки фокусного расстояния: -18…+22 мм;

- Поддержка линз с фокусным расстоянием 150 мм.

Оптическая головка LH-110

LH-105 (снято с производства)

Оптическая головка LH-105 - это популярная модель в линейке лазерных головок LH.

Технические характеристики LH-105

- силовой обдув точки врезки при пробивке материала;

- интегрированный датчик системы слежения FoCut;

- быстрая (картриджная) замена фокусирующей линзы;

- быстрая (картриджная) замена защитной пластины;

- диапазон регулировки фокусного расстояния: -20…+20 мм;

- изменение положения линзы (точки фокуса) «на лету» (в том числе при пробивке материала);

- автоматическое изменение положения линзы при выборе материала из библиотеки;

- поддержка линз с фокусным расстоянием 150, 200, 300 мм;

- коллиматор с регулировкой фокусного положения линз позволяет добиться наилучшего качества резки, работать с большими толщинами, увеличить скорости резки;

- электромеханический привод линзы;

- управление положением линзы с ЧПУ;

- поддержка линз диаметром 1” и 1,5”;

- обдув защитной пластины;

- датчик температуры сопла;

- охлаждение сопла.

Оптическая головка LH-105

LH-103 (снято с производства)

Разработанная нашей компанией оптическая головка LH-103 поднимает автоматизацию процесса лазерной резки на совершенно новый уровень. Автоматическая регулировка фокусного расстояния, благодаря встроенному приводу линзы, не только облегчает настройку режима резания, но и повышает скорость пробивки материала за счёт смещения точки фокуса в момент прожига.

Картриджная система замены линз и защитных пластин значительно сокращает время обслуживания оптической головки и ускоряет процесс замены фокусирующей линзы.

Картриджная замена линзы и защитного стекла

Картриджная система замены линз и защитных пластин значительно сокращает время обслуживания оптической головки и ускоряет процесс замены фокусирующей линзы.

С новой системой для замены линзы и защитного стекла достаточно всего лишь сдвинуть фиксаторы, вытащить картридж и заменить его на запасной.

Воздушное охлаждение сопла

Технологический газ подается в оптическую головку. Выходя из сопла под высоким давлением, он расшлаковывает зону лазерного реза («выдувая» металл). Также газ обдувает защитное стекло, очищает его, и дополнительно предохраняет объектив от продуктов сгорания материала.

Технические характеристики LH-103

- электро-механический привод линзы;

- управление положением линзы С ЧПУ;

- автоматическое изменение положения линзы при выборе материала из библиотеки;

- обдув защитной пластины;

- охлаждение зоны резания;

- силовой обдув точки врезки при пробивке материала;

- интегрированный датчик системы слежения FoCut;

- встроенный автоматический привод картриджа фокусирующей линзы;

- быстрая (картриджная) замена фокусирующей линзы;

- быстрая (картриджная) замена защитной пластины;

- диапазон регулировки фокусного расстояния: -20…+20 мм;

- изменение положения линзы (точки фокуса) «на лету» (в т.ч. при пробивке материала);

- поддержка линз с фокусным расстоянием 150 и 200 мм;

- поддержка линз диаметром 1 и 1,5 дюйма.

Преимущества лазерных оптических головок LH:

- увеличенная производительность резки;

- улучшенное качество реза;

- оптимальные режимы пробивки;

- увеличенный срок службы расходных материалов;

- быстрое и удобное обслуживание;

- максимальная автоматизация процесса резки.