Линейный привод

Ниже приведены схемы реализации линейного перемещения трех видов наиболее распространенных кинематических схем портального механизма, которые используются в современном станкостроении: шарико-винтовой пары (ШВП), реечной передачи (шестерня-рейка) и линейного двигателя (прямого привода).

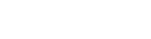

Шарико-винтовая пара

- Элементы, подверженные механическому износу

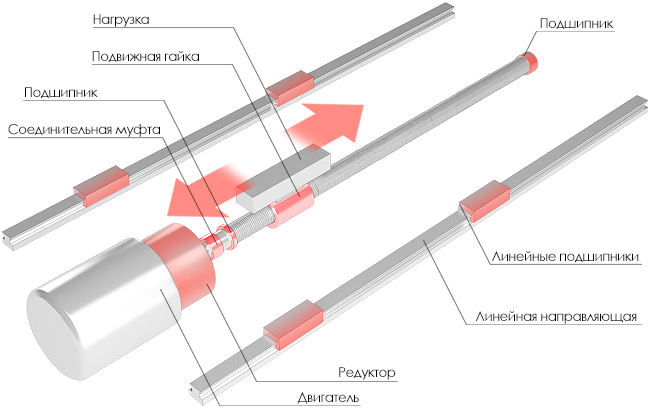

Реечная передача

- Элементы, подверженные механическому износу

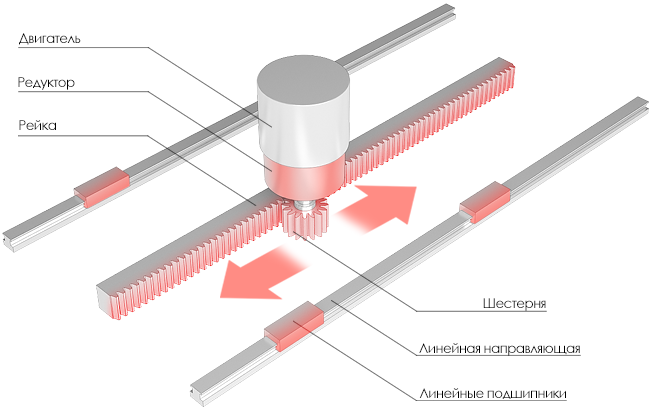

Линейный двигатель

- Элементы, подверженные механическому износу

- Элементы, не подверженные механическому износу

Сравнение ШВП с прямым приводом

Конструкция ШВП предполагает большое количество механических сопряжений, что приводит к износу частей шарико-винтовой пары и как следствие потери точности обработки. В свою очередь, линейный двигатель состоит всего из двух частей, взаимодействие которых происходит исключительно на электромагнитном уровне. Механического контакта между частями нет, следовательно, нет механического износа самого линейного привода.

Следует отметить, что присутствует дополнительная сложность реализации систем ШВП для длинных ходов, что обусловлено дополнительными механическими напряжениями вследствие прогиба винта. Для таких систем требуется точный инженерный расчёт и использование высококачественных комплектующих. Поэтому производители, не обладающие достаточным инженерно-научным потенциалом, делают координатные системы ШВП с низкой надёжностью, либо избегают её использования.

Сравнение особенностей реечной передачи с прямым приводом

Реечная передача лишена таких недостатков ШВП, как прогиб и высокая инерционная нагрузка на двигатель, но требует ещё более высококачественного исполнения координатной системы: высокоточной установки направляющих, зубчатой рейки, редуктора и двигателя. При должном качестве изготовления станины и сборке, современная зубчатая передача на основе закалённой шестерни-рейки обеспечит длительную и стабильную работу станка.

Однако погрешности в изготовлении станины или установке направляющих могут привести к появлению люфтов и быстрого механического износа привода. Поэтому, как и в случае с ШВП, производители, не обладающие опытом и технологиями высокоточного изготовления координатных систем, либо не могут обеспечить должной надёжности станка, либо избегают использования реечной передачи.

Рассмотрим процесс управления в каждом случае

ШВП и реечная передача содержат большое количество элементов, способных со временем подвергаться износу: вал, шкив, винт, шарики, гайку и т.п. Линейный двигатель в свою очередь содержит только ротор и статор, разделенные воздушны зазором. Между источником энергии и рабочим органом не располагается никаких промежуточных элементов, а передача энергии осуществляется через воздушный зазор. Благодаря отсутствию механических сочленений линейный привод лишен механических люфтов.

В силу меньшего количества этапов преобразования электрической энергии в поступательное движение, линейный привод обладает лучшим КПД, нежели привод на ШВП или зубчатой рейке.

Сравнение характеристик различных типов приводов

Износ

В отличие зубчатой передачи и координатных систем на ШВП, линейный привод не содержит механических компонентов, поэтому обладает высокой степенью надежности и не подвержен износу.

Люфты

Механические люфты системы напрямую влияют на повторяемость позиционирования координатной системы. В силу большего количества механических сочленений координатные системы на ШВП и зубчатой рейке имеют большую величину механического люфта, тогда как координатные системы на линейном приводе лишены механических люфтов.

Точность на длинных ходах

Точность на длинных ходах в случае координатной системы на линейном приводе определяется точностью системы обратной связи по положению (магнитной или оптической линейкой), а также точностью установки портала (прямого угла) и самой системы слежения. В случае координатных систем на основе ШВП или зубчатой рейки, точность определяется качеством изготовления станины и установки направляющих. В обоих случаях, чтобы компенсировать отклонения на больших ходах, требуется калибровка координатной системы при помощи лазерного интерферометра. При отсутствии надлежащего качества производства и инженерно-технических возможностей для калибровки координатной системы, использованием прямого (линейного) привода является более предпочтительным в силу своей простоты.

Динамика

Координатные системы на базе ШВП и зубчатой рейки значительно уступают линейному приводу в том, что касается динамических характеристик. Основной причиной этому являются их конструктивные и технологические особенности (большое количество промежуточных элементов, зазоры, резко меняющееся трение во множестве сопрягаемых деталей, погрешности в шаге винта и многое другое). Все это со временем сказывается на динамических характеристиках станка.

В свою очередь, в системах с линейным приводом решены вопросы обеспечения требуемых динамических характеристик как при управлении траекторией движения, так и при обеспечении должной точности позиционирования.

Надёжность

В силу меньшего количества механических компонентов и сочленений система на линейном приводе обеспечивает наиболее высокий уровень надёжности. Однако, всегда следует помнить, что привод является не единственным компонентом станка лазерной резки, и следует оценивать общую надёжность системы в целом.

Точность контурных перемещений мало зависит от типа привода и определяется в первую очередь механической жёсткостью конструкций координатной системы (в т.ч. портала), а также частотным ответом координатной системы (который, в свою очередь, зависит от конструктивных особенностей портала, крепления головки и других компонентов).

Точность контурных перемещений также связана с динамическими характеристиками координатной системы. Установив мощный привод можно добиться высокой динамики на холостых ходах (с отключенным инструментом), но для обеспечения точности, если конструкция станка недостаточно жёсткая, требуется значительное понижение значений ускорений и торможений.

Стоимость

Координатная система на линейном приводе дороже, чем координатная система на ШВП или зубчатой рейке. Это объясняется тем, что для прямого привода требуется длинная «магнитная дорога», вдоль которой и движется привод, собранная из мощных неодимовых магнитов. В то время как у обычного серводвигателя количество таких магнитов значительно меньше и они находятся на роторе, который поворачивается множество раз в пределах рабочего хода координаты.

Таблицу можно прокручивать влево/вправо

| Координатная система на ШВП | Координатная система на зубчатой рейке | Линейный двигатель |

|---|---|---|

| Подвержена износу. Высокий износ при некачественном изготовлении. | Подвержена износу. Высокий износ при некачественном изготовлении. | Отсутствие изнашиваемых компонентов. |

| Наличие люфтов в тележках и приводе, влияющих на точность. | Наличие люфтов в тележках и приводе, влияющих на точность. | Отсутствие механических люфтов. |

| Снижение точности на длинных ходах. | Снижение точности на длинных ходах. | Высокая точность на любых ходах. |

| Средняя динамика. | Высокая динамика перемещения (при использовании мощного привода). | Высокая динамика перемещения (при использовании мощного привода). |

| Высокая надёжность при должном качестве изготовления. | Высокая надёжность при должном качестве изготовления. | Высокая надёжность. |

| Средняя стоимость. | Средняя стоимость. | Высокая стоимость. |

Выводы

Линейный привод обладает рядом неоспоримых преимуществ, по сравнению с ШВП или реечной передачей. Сам по себе линейный привод увеличивает срок службы оборудования, повышает точность координатной системы и динамику перемещений.

При этом нельзя утверждать, что использование ШВП и зубчатой рейки больше не актуально в современном станкостроении. При должном качестве изготовления, данные схемы перемещения хорошо характеризуют себя в технике начального уровня - маломощных станках, для которых не предъявляется высоких требований к скорости и количеству выпускаемой продукции. Тем не менее, для станков более высокого уровня - линейный привод по-прежнему остается наиболее эффективным решением, обеспечивающим высокую динамику и прецизионную точность позиционирования.

Компания Unimach производит станки на всех трёх типах приводов: ШВП, зубчатой рейке и линейном (прямом) приводе, что позволяет всегда предложить наиболее эффективное решение с точки зрения цены, производительности и надёжности для каждой задачи.