Программное обеспечение UniCut

UniCut

Разработанное нашей компанией программное обеспечение UniCut имеет простой, ориентированный на пользователя интерфейс. В ПО UniCut реализованы функции, существенно упрощающие и оптимизирующие процесс раскроя: пауза обработки, обратный ход по контуру, быстрый переход к любой врезке, быстрое изменение точки врезки, начало резки с любого места контура и т.д.

ООО «НПК МСА» является правообладателем товарного знака «UNICUT» по свидетельству Российской Федерации № 695075, также по свидетельству российской Федерации № 980685.

Настоящее программное обеспечение (далее – ПО) предназначено для управления установками лазерной резки производства компании ООО «НПК МСА».

ПО поставляется в комплекте с приобретаемой установкой лазерной резки либо по запросу через службу поддержки у предприятия-изготовителя.

Классификатор программы 08.06 – Средства управления оборудованием с числовым программным управлением (САМ) [Программное обеспечение (модули), которое должно быть предназначено для подготовки управляющих программ для станков с числовым программным управлением].

Функциональные характеристики ПО

ПО UniCut обеспечивает следующие возможности:

- выгрузка, создание и редактирование планов обработки деталей, сборок и контуров обработки;

- настройка основных исполнительных механизмов установки лазерной резки и выбор команд, осуществляющих управление программами обработки;

- управление дополнительным оборудованием и задание настроек для него;

- сохранение сборок и деталей в файл на жестком диске и их загрузка в ПО.

Качество и производительность

-

FlyCut

Технология FlyCut позволяет существенно сократить время обработки тонколистовых металлов за счёт обработки не отдельных контуров, а сквозных траекторий, образуемых группами контуров, которые станок проходит без разгонов и торможений. Экономия времени особенно велика при резке перфорированных решеток. Подробнее

-

FineCut

Технология FineCut предназначена для высококачественной обработки сложных контуров. Функция позволяет обрабатывать определённые участки контуров (углы, близко расположенные участки) в импульсном режиме. Переключение между FineCut и обычным режимом осуществляется автоматически в соответствии с настройками. FineCut позволяет установке переключаться между непрерывным и импульсными режимами резки даже в пределах одного контура. Подробнее

-

Управление мощностью излучения в зависимости от скорости

Для получения качественных острых и прямых углов мощность лазерного излучения автоматически регулируется в зависимости от моментальной скорости движения оптической головки. При снижении скорости движения оптической головки (например, на углах) выходная мощность излучения снижается в соответствии с параметрами, заданными в настройках, что предотвращает выгорание углов.

-

Автоматическое создание программ резки

ПО UniCut обеспечивает быстрое и интуитивно понятное составление программ резки, которое осуществляется двумя кликами мыши. Производится автоматическое определение вложенности контуров и автоматический расчет оптимальных проходов. Данная функция весьма актуальна для малых предприятий, при работе с малой серийностью, но большой номенклатурой заказов.

-

Зоны безопасности

Зоны безопасности — области, на которых установлены прижимы листа или держатели. При попадании оптической головки в такие зоны контур детали не обрабатывается, а станок встает на паузу. Размер зоны безопасности (мм) задаётся оператором. Зоны безопасности учитываются при построении безопасных проходов.

-

Безопасные проходы

Иногда вырезанные детали поднимаются над листом и могут стать препятствием на пути движения оптической головки. Функция генерации безопасных проходов позволяет автоматически обходить такие участки. Программа прокладывает путь между контурами так, чтобы он не попадал в зоны, где уже был вырезан металл.

Экономика и управление

-

Журнал мастера

Дистанционная постановка и контроль выполнения поставленных задач позволяет минимизировать бумажный документооборот и обеспечить постановку задач на станок через локальную сеть с рабочего места мастера. Электронная постановка задач позволяет эффективнее организовать производственный процесс, поскольку систематизация в этом случае (по материалу, приоритету, изделию) осуществляется автоматически. При наличии на производстве нескольких раскройный комплексов модуль постановки и контроля задач позволяет балансировать нагрузку между машинами.

-

Статистика производства

ПО UniCut производит автоматический расчет времени обработки деталей, коэффициента использования материала, количества деталей. Реализована функция счётчика вырезанных деталей. Таким образом существенно упрощается расчет стоимости, например, при резке сторонних заказов а также расчет себестоимости продукции.

-

Простота ПО

Простота программного обеспечения UniCut позволяет сократить время обучения специалиста средней квалификации базовой работе на станке. Стоимость работы специалиста будет гораздо ниже, чем высококласного специалиста, что положительно сказывается на себестоимости продукции. Программное обеспечение UniCut обновляется компанией Unimach бесплатно в течение всего срока эксплуатации установки.

Удобство работы и сервиса

-

Отдельная настройка режимов прожига, гравировки и резки

Режимы прожига, гравировки и резки настраиваются оператором по отдельности до начала резки. Оператору не придется останавливать процесс обработки материала, чтобы перенастроить станок и ввести новые уставки, т.к. переключение между режимами происходит автоматически. Это позволяет не только существенно увеличить производительность раскройного комплекса, но и сократить затраты на расходные материалы.

-

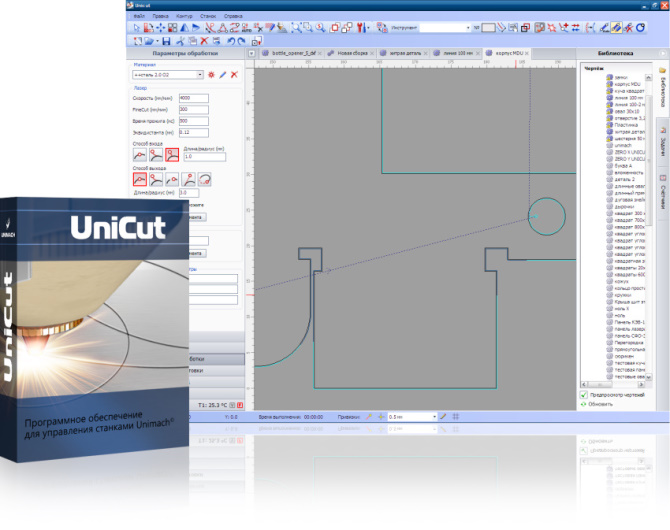

Удобный графический интерфейс

Настройка оборудования, загрузка и создание программ, производятся оператором при помощи удобного, интуитивно понятного, графического интерфейса. Графическая информация воспринимается гораздо лучше, чем сухие наборы цифр, поэтому с подобным оборудования приятнее и эффективнее работать, а сама настройка системы происходит намного быстрее.

-

Библиотека материалов

ПО UniCut имеет библиотеку материалов, обеспечивающую не только хранение настроек под определенный материал, но и автоматическую загрузку параметров в модули станка при выборе материала.

-

Безусловный комфорт

Интерфейсы управления всем перифирийным оборудованием станка интегрированы в одну программную оболочку. Дополнительным удобством для оператора является контроль над всеми модулями раскройного комплекса с одного рабочего места.

-

Таймеры обслуживания

Для регулярного технического обслуживания станка в ПО предусмотрены автоматические таймеры обслуживания с индикацией времени замены расходных материалов. Программное обеспечение автоматически считает наработку узлов раскройного комплекса и своевременно выдает сообщения о необходимом сервисном обслуживании.

-

Дистанционная диагностика

Функция дистанционной (через Интернет) диагностики неисправностей систем станка позволяет свести к минимуму время простоя станка и исключить выездные расходы в случае решения сервисных вопросов, связанных с неправильной настройкой оборудования.

FineCut

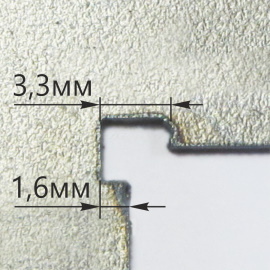

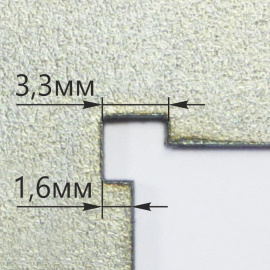

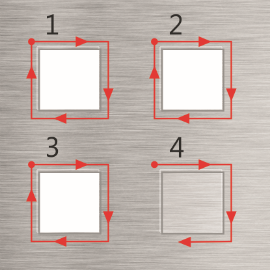

FineCut используется при обработке сложных контуров. Функция позволяет обрабатывать определённые контуры (углы, близко расположенные контуры) в импульсном режиме. Переключение между FineCut и обычным режимом осуществляется автоматически в соответствии с настройками.

Образцы резки

Образцы резки стали 1,5 мм (кислород, 6000 мм/мин) в обычном режиме

Образцы резки стали 1,5 мм (кислород, 6000 мм/мин) с использованием режима FineCut

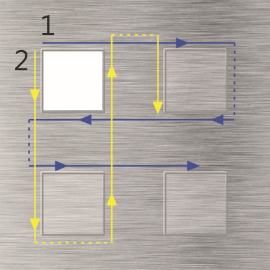

FlyCut

Данный метод может существенно сократить время обработки тонколистовых металлов, т.к. осуществляет вырезку не каждой детали по отдельности, а всех контуров, лежащих на одной прямой. Оптическая головка в высоком темпе построчно проходит весь лист, производя вырезку контуров на соответствующем отрезке. Экономия времени особенно заметна при резке перфорированных решеток.

Обычный режим

Flycut