MultiWeld

Laser welding

Automatic laser welding machine MultiWeld – is a pilot project of NPK Morsvyazavtomatica. It enables welding of rotary parts, outside welds of complicated workpieces with several facets, linear (one-axis), two-axis and three-axis welding.

An operator can effortlessly change settings to process next workpiece due to the modular design and wide range of clamp assemblies and supports. MultiWeld is an unparalleled machine among welding equipment of this price segment. Unlike our rivals that work with limited range of products, MultiWeld enables to weld different types of workpieces. It performs functions of several machines at the same time significantly saving space of working facilities.

Laser, optic fiber and weld gun can work as a stand-alone system – LaserWeld manual laser welding unit - and run independently from the machine. Not limited by the worktable size the unit enables to expand a range of processed workpieces. Coordinate system and working table together with all modules may be used for quenching, cladding and cleaning. An operator just needs to equip the machine with a suitable unit.

Features:

Modular design

Universal machine design combines functionality of linear (one-axis), two-axis and three-axis welding, welding of outside corners, as well as girth welding in two dimensions within one system.

Saving workspace

Different welding operations may be carried out within one workplace significantly saving space of working facilities and time for weldment production.

No distortion

The risk of distortion is eliminated due to minimum area of heating.

No post processing

MultiWeld products do not need post processing exponentially decreasing their prime costs.

Additional axes of weld gun

Special mounting with different angles enables to fix a welding gun and ensure operation at different angles relative to vertical.

Extended functionality without significant modifications

Design of coordinate system enables to integrate it with welding semi-automatic machine MIG, TIG torch, and manual laser cleaning machine without effort.

Modular design:

Welding module for rotary parts

The module enables 360° rotation of cylindrical workpiece in any direction. It may have horizontal (for long workpieces) and vertical orientation (for workpieces under 200 mm).

Welding table

Different clamping assemblies and supports fix a workpiece on the welding table during processing and ensure various welding operations.

Corner module

A perfect solution for corner welding of complicated workpieces with several facets. The module consists of an automatic clamping device and central support. The welding angle is adjusted by means of modular supports.

Adjustable table

The table motion ensures 3 axis welding. The height may be adjusted depending on the workpiece size. Rack and pinion allows for the travel along X axis.

Main technical data

| General specifications | |

|---|---|

| Laser power, W | 1000-2000 |

| Coordinate system | 4 CNC-controlled axes |

| Х axis travel, mm | 650 |

| Y axis travel, mm | 2580 |

| Z axis travel, mm | 200 |

| X, Y, Z axes travel speed m/min | Synchronously up to 120 |

| Accuracy of repetition, mm/m | ±0,1 |

| Max. workpiece diameter (horizontal orientation of rotation module), mm | 200 |

| Max. workpiece diameter (vertical orientation of rotation module), mm | 1,000 (max. height 200 mm) |

| С axis rotation speed, rot/min | 120 |

| Positioning accuracy, mm/min | ±0,1 |

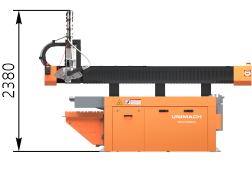

| Overall dimensions, L х W х H, mm | 3450 х 1450 х 2250 |

| Max. weight, kg | 2000 |

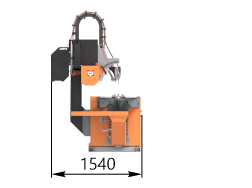

Overall dimensions, mm

Overall dimensions MultiWeld