IPG FL-CPM

Laser welding

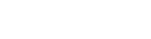

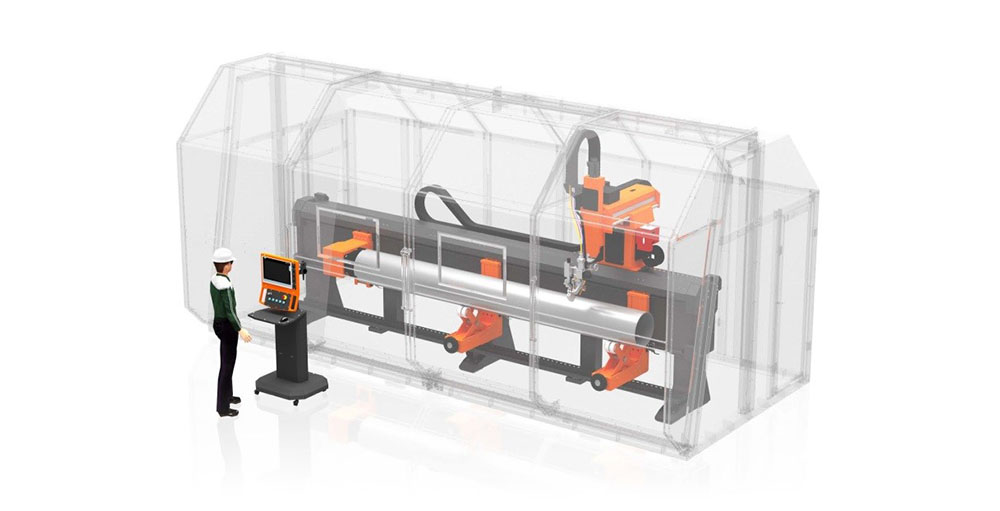

Laser welding machine for rotary parts FL-CPM – is a universal solution based on IPG ytterbium fiber laser technology. Owing to automation of complicated technological processes, the system ensures welding of parts with poor fit-up and different thickness. End products require almost no post-processing, significantly reducing the cost of production.

The modular design and wide range of supports enable to work with different types of workpieces. Due to quick and simple settings, an operator may easily adjust and/or dissemble supports to swap a workpiece.

Coordinate system enables to change a tube rotating device and steady rest to other devices for square tubes, flat workpieces, angles, etc. exponentially increasing range of workpieces and creating unique configuration of the machine. On top of that, an operator may switch a type of processing just by swapping a welding head for cutting or cladding one, without any additional changes.

Features

4 axes of simultaneous motion

3 motorized axes of linear path (X, Y, Z axes) and axis of workpiece rotation (axis А). Moreover, FL-CPM may be equipped with two additional rotation/tilt axes.

High precision welding

Welding head drive and supports are located on the single element ensuring high precision welding and preventing from distortion.

IPG software

Intuitive and user-friendly software.

Modular design

Wide range of different supports enables to transform working area for any technological purpose.

No distortion

Local surface processing. Heat affected area is less than 0.5 mm.

Automatic seam tracking system

Welding head may be optionally equipped with a triangulation sensor to track seam and tool path.

Integrated beam oscillation system (Wobble)

Choice of welding seam width (up to 5 mm) and oscillation frequency of output beam results in excellent welding quality of parts with poor fit-up.

Main technical specifications

| Specifications | |

|---|---|

| Fiber laser | LS series, up to 10 kW |

| Coordinate system | 4 CNC-controlled axes (up to 6 axes at option) |

| Х axis travel, mm | 4550 |

| Y axis travel, mm | 485 |

| Z axis travel, mm | 350 |

| X axis travel speed, mm/s (idle / work) | 500/150 |

| Accuracy of repetition, mm | ±0,05 |

| Capacity, kg | 2000 |

| Max. workpiece diameter, mm | 500 |

| С axis rotation speed, rot/min | 0-20 |

| Max. error of rotation axis, mm | ±0,1 |

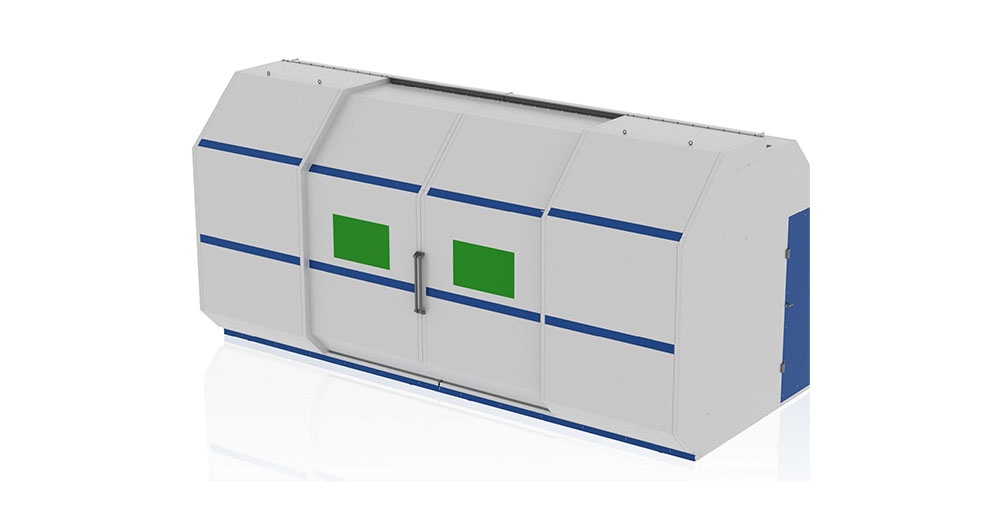

| Overall dimensions L х W х H, mm (w/o cable protection) | 6500 х 2500 х 3400 |

Scope of delivery:

- Laser welding machine for rotary parts;

- Ytterbium fiber laser LS-10*;

- Water-air cooling system: chiller IPG LC 340*;

- Optical welding head with HLC-8 connector, FLW D50 Wobbling IPG*;

- Filler wire feeding mechanism;

- System of optical head movement and workpiece rotation, two linear coordinates;

- Control cabinet;

- Control console with HMI touch panel and remote control panel.

Note: *- Final scope of delivery depends on Customer’s technical specifications