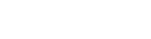

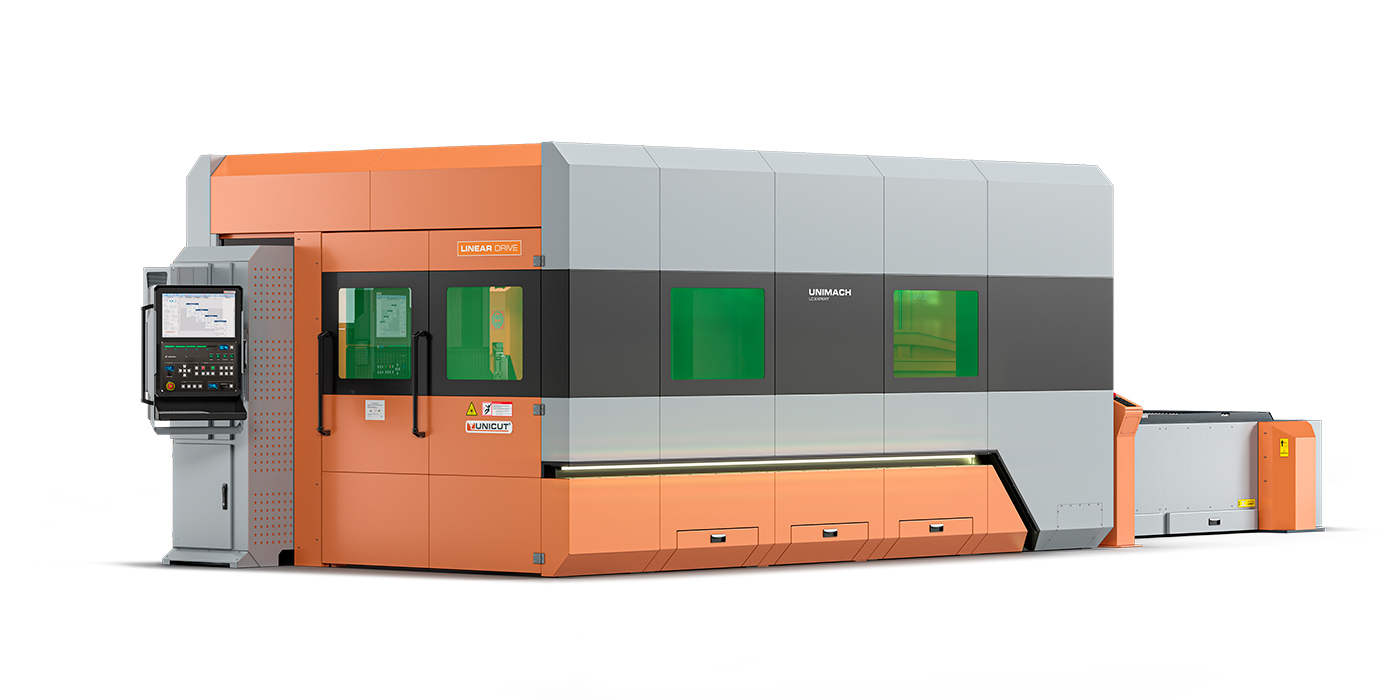

LC Expert

Laser cutting machine

Description

Laser cutting machines Expert series outstand Unimach production line due to the extreme efficiency. This solution will perfectly meet the needs of Medium& Large Enterprise. The wide range of additional automation significantly minimizes downtime of the equipment.

Unimach machinery is manufactured in St Petersburg using our own components.

Standard equipment

- Rigid all-welded heat-treated machine bed with subsequent machining

- Gantry coordinate system

- Light-weight composite portal

- High precision guides, integrated feedback

- Linear drive, axes X, Y

- Zoned smoke exhaust system with automatic zone switching

- Ytterbium fiber laser IPG Photonics

- Cooling system water / air (chiller)

- Focus length control system FoCut

- Laser optical head with automatic drive of focus lens LH-110

- Control console UM-103 (IP65, industrial LCD 21", stationary control panel, pull-out keyboard)

- Software UniCut

- Automatic 4-gas console (2 gases up to 10 atm, 2 gases up to 20 atm)

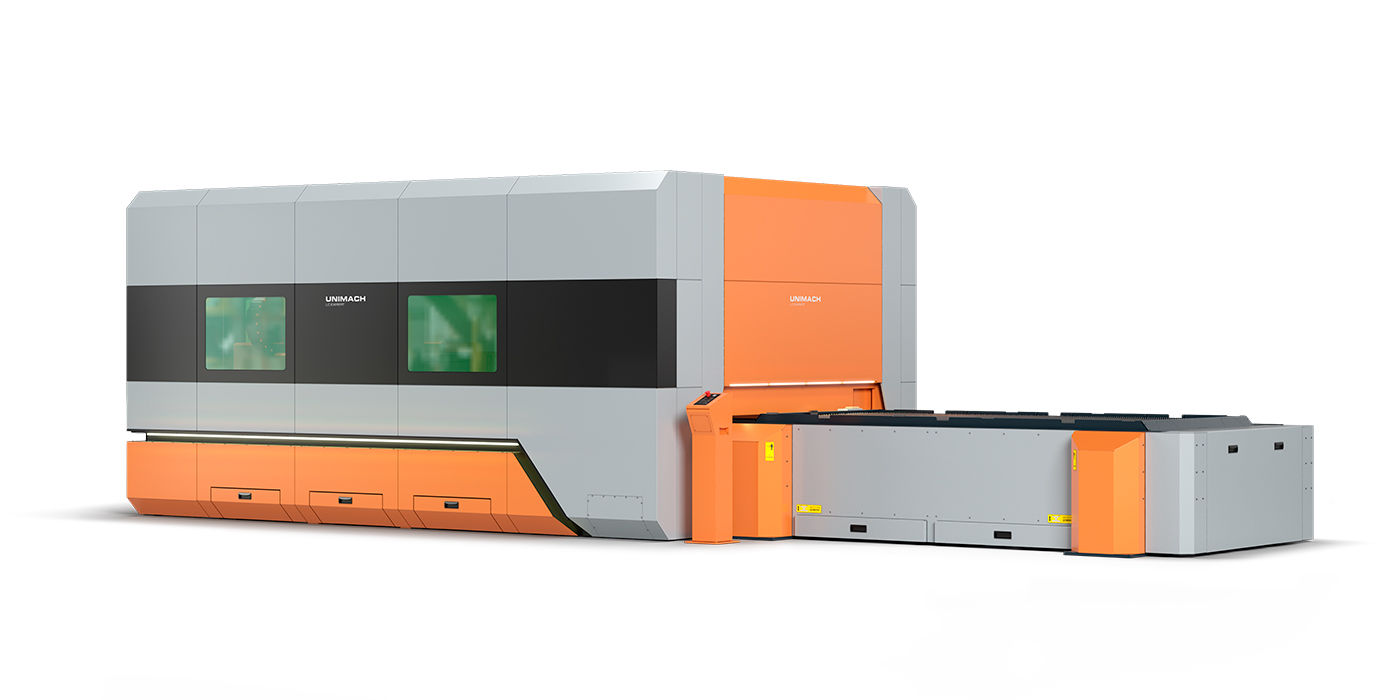

- Cabinet protection of cutting area with an access to working table

- Automatic shuttle table

- SPTA kit

- Commissioning works and personnel training

Main specifications

| Emission source | |

|---|---|

| Type | Ytterbium fiber laser |

| Power, W | 3000-15000 |

| General specifications | ||

|---|---|---|

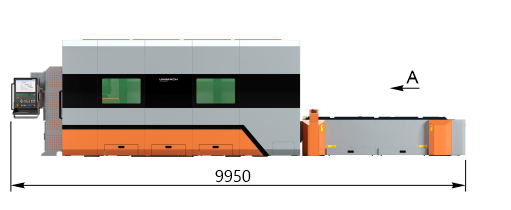

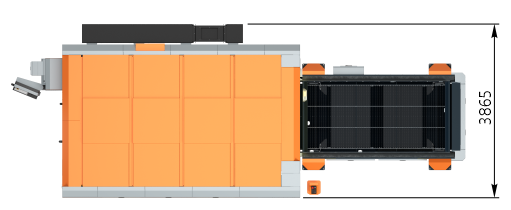

| Model | LC Expert FO3015 | |

| Processing area, mm | 3020х1520 | |

| Weight (max), kg | 13600 | |

| Max load to table, kg | 1100 | |

| Overall dimensions, mm | ||

|---|---|---|

| Length | 9645 | |

| Width | 3675 | |

| Height | 2375 | |

| Accuracy * | |

|---|---|

| Positioning accuracy in all axes, mm | ±0,05 |

| Accuracy of repetition, mm | ±0,025 |

* Accuracy depends on the workpiece type, preprocessing, sheet size and position at the working area. According to standard VDI/DGQ 3441 measurement length complies with 1 m.

| Speed and acceleration | |

|---|---|

| Speed of free movement along the axes X, Y, Z (m/min) | up to 220 |

| Acceleration / deceleration along the axes X, Y, Z | up to 3,5 G |

| Linear axes | |

|---|---|

| Linear drive with precision measurement scale | |

| Linear drive with precision measurement scale | |

| Servo drive with zero backlash gear, additional tracking feedback, precision rack & pinion | |

Overall dimensions of the machine

Control console UM-103

Control console is a separate dust-proof console equipped with an LCD to represent operating data. All controls and LEDs are located in front of the operator at the front panel. Such layout allows an operator to react within the shortest time and prevent any possible errors.

To provide additional comfort the console has special drawers to store consumables or tools, and a holder for papers. CNC console is equipped with two USB ports to connect flash drives or download drawings and programs. A LAN port to integrate a machine to general manufacturing system is located on the back panel.

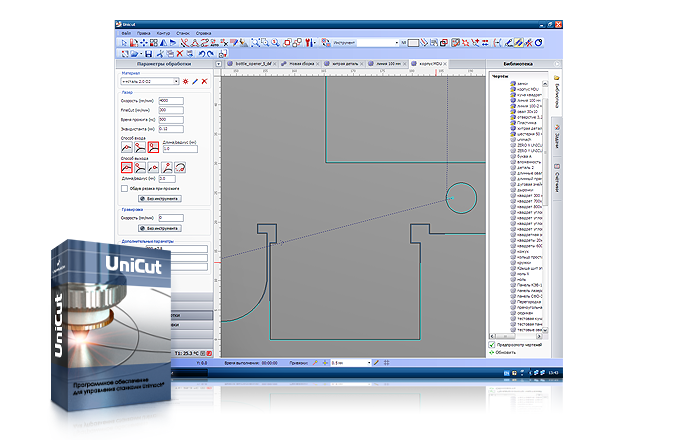

UniCut software

User-friendly UniCut software is a proprietary development of Unimach®. To simplify and optimize cutting process UniCut provides the special functions such as pause, back move along the contour, quick transition to any piercing, quick change of piercing point, start of cutting can be carried out from any point of contour, etc.

Control operations from your workplace using one program

All control interfaces of the machine units are integrated in one program. All cutting machine modules can be controlled from one workplace to provide additional comfort.

Individual settings for laser piercing, engraving and cutting

Laser piercing, engraving and cutting modes can be set individually before the cutting process. There’s no need to stop the process in order to change or enter the new settings. Switching among the modes occurs automatically leading to higher production capacity of the cutting machine.

Laser power can be controlled depending on the speed

To reach higher quality of sharp and right angles laser power can be controlled automatically depending on the speed of optical head. At the zero speed (at the moment of stop at the corner) output power equals to minimum power configured in the settings which prevents the corner from a burnout.

Library of materials

UniCut software includes the Library of materials, where a user can find recommended settings for particular materials or use a special function to create new ones.

Automatic program creation

UniCut software can help you to create a cutting program quickly and intuitively, in a few clicks. The program automatically detects nested contours and calculates the most optimal travels. This function is useful for small enterprises that are dealing both with small batches and a wide range of products.

User-friendly interface

Provide the settings quickly using our user-friendly graphic interface. Graphic data is easier to percept than endless lines of digits, it saves your time and makes workplace’s atmosphere more comfortable.

Maintenance timers

Software maintenance timers help to provide technical maintenance on schedule indicating time for replacing consumables. The software automatically calculates working hours for machine units and notifies an operator about the required service.

Production statistics

UniCut software automatically calculates time for workpiece processing, beneficial use of materials, number of parts. Received data significantly simplify cost calculations, e.g., calculations for third-party orders, costing production and waste.

Remote diagnostics

Remote diagnostics of system malfunction (through the Internet) makes it possible to reduce downtime of the machine and cut down off-site expenses concerned with wrong settings of the equipment.

Operator’s log

Working objectives can be set and controlled remotely from the operator’s workplace reducing paperwork and setting objectives through the network. That helps to organize working process more efficiently because systematization (materials, priority, product) is done automatically in this case.

Intuitive and user-friendly software

Simple and intuitive UniCut software saves time for staff training: a mid-level specialist can be quickly taught some basic operations with the machine. The cost of mid-level specialist work will be less than highly-skilled professional resulting in lower product cost. Software also allows for monitoring and control of tracking system, cooling system, laser and log of module operation data. Free updates.

UniCut mainframe window

Focus length control system FoCut

Automatic tracking system Focut of our machines controls a stabile position of an optical head with precision of 0.1 mm within the wide range of heights. It ensures precise cutting both on the workpiece edge and highly deformed metal sheet. The system includes the following capabilities. Learn more

The system includes the following capabilities:

Jump up piercing. At the moment of piercing an optical head is uplifted to the specified height preventing the nozzle from contamination by the melted metal. Then the further cutting is carried out from the specified focus length. This method helps to use the consumables - a nozzle and protective glass - efficiently and avoid possible errors or malfunction.

Fly cutting (without stopping to pierce the material). This method crucially reduces the time for processing thin sheets as the machine cuts all contours which are located along one line (and not each separate pattern). An optical head moves all over the workpiece cutting the contours of the relevant area. This function is perfect for cutting perforated grilles.

Pre-heating of the cutting area. Cutting thick material requires pre-heating. An optical head uplifts at the height set by an operator and heats the cutting area; then the optical head goes down and cuts the material.

Shortened height. While moving from one piercing point to another an optical head is not uplifted to the maximum height; it is lifted at the shortened height, therefore saving time and increasing the efficiency of the machine.

Automatic calibration of the optical head. Automatic calibration system ensures calibration at every piercing point. This function maintains high quality even when cutting the strongly deformed metal.

Graph display of dynamic and operating parameters. A graph is a convenient, simple and time-saving way to estimate operation of tracking system and detect errors.

FoCut system also allows for processing non-metallic materials.