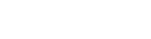

TCU-Professional

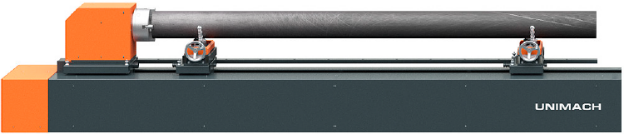

Module for tube cutting

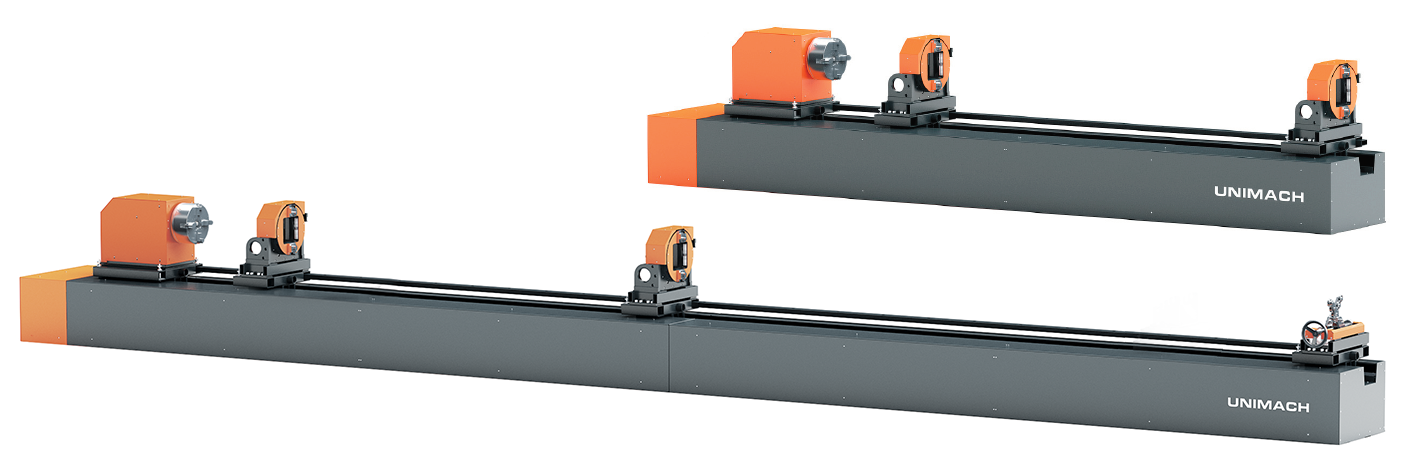

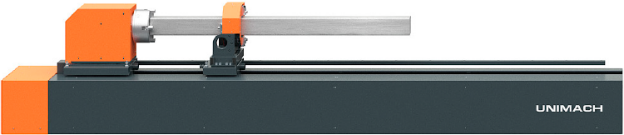

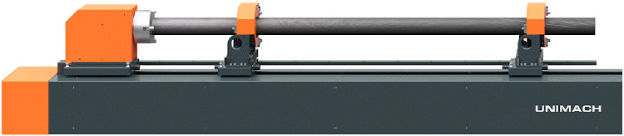

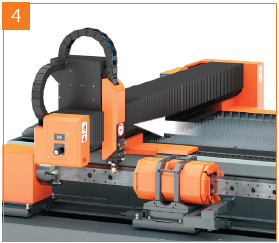

Module for round tube cutting TCU-Professional is combined with laser cutting machines LC Standart, LC Master, LC Professional M2 and allows for cutting tubes along the length, engraving, as well as cutting out holes of any complexity and grooves.

Unimach machinery is manufactured in St Petersburg using our own components.

TCU-Professional Features

- Cutting operations can be carried out near the supporting steady rest which lead to high precision cutting of tubes deformed due to manufacturing

- Bowed tube is measured before the cutting in order to compensate it

- Zero backlash steady rests to support a workpiece

- Machine body is optimized by anchor reinforcement

- Shaped tube cutting at angle

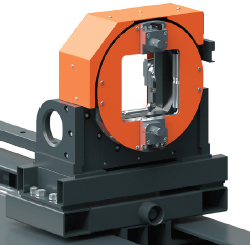

- Universal steady rest to support shaped and round tubes

Features of Unimach tube cutting modules

High performance

Laser cutting machines Unimach are optionally equipped with modules for round and rectangular tube cutting, combining processing of flat sheets and precision tube cutting. Simple and intuitive change of cutting operations leads to increased efficiency.

Intuitive control

All Unimach equipment is controlled from one workplace using one software. Simple and user-friendly interface allows for carrying out many repeated operations automatically.

The highest cutting quality

Special function of Unimach software measures the tube curve and corrects received data which leads to precision processing of workpieces with damaged geometry.

Specifications:

- Max. size of square tube, mm: 175x175 (diagonal inscribed in Ø250mm)

- Max round tube diameter: 250 mm

- Max tube length: 3000 mm

- Max thickness of tube wall: 10 mm

- Max weight: 300 kg

- Compliant with cabinet protection

Rotary axis parameters:

- Rotary axis drive: servo drive

- Positioning accuracy: ±0.1 mm/m

- Repeatable accuracy: ±0.1 mm/m

- Max speed: 120 rot/min

TCU-Professional configuration

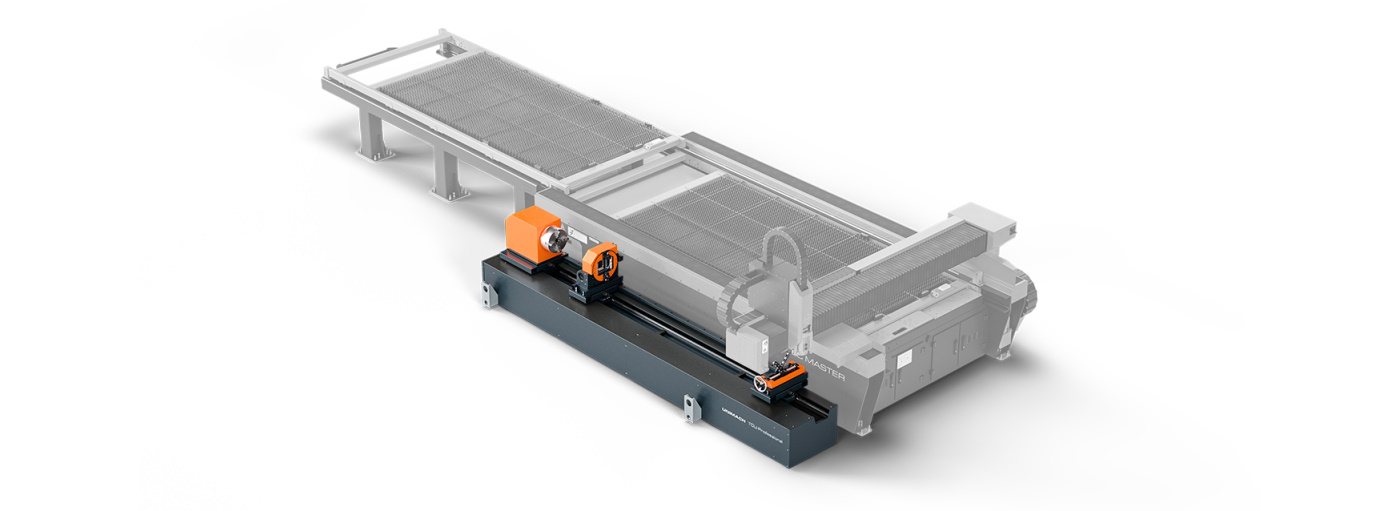

-

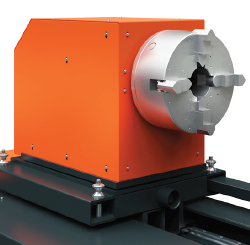

M1 Main module for holding and rotation of rectangular and round tubes

M1 Main module for holding and rotation of rectangular and round tubes -

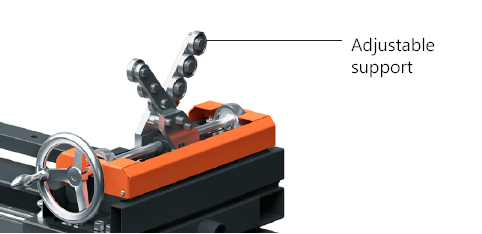

M3 Manual steady rest for rectangular and round tubes

M3 Manual steady rest for rectangular and round tubes -

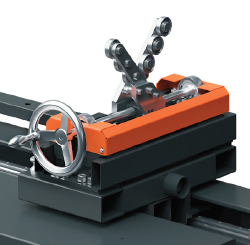

M4 Steady rest to support round tubes

M4 Steady rest to support round tubes

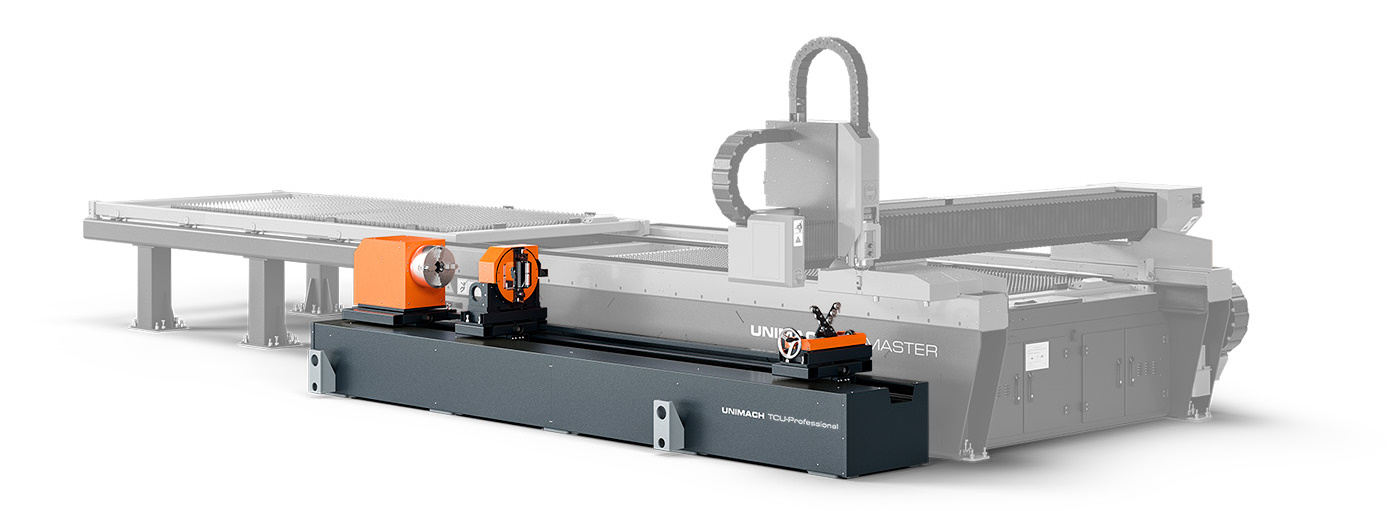

Modules for tube cutting TCU-Professional are equipped with steady rests to support rectangular and round tubes, as well as additional module to process the tubes up to 6000 mm.

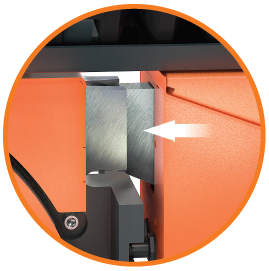

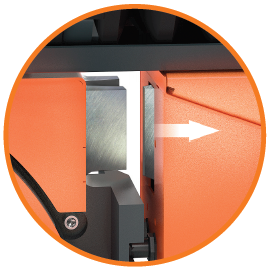

Manual steady rest

Manual steady rest locks and unlocks rectangular and round tubes using a special plug wrench.

- Max cross-section 150х150 mm

Max length 3000 mm

- Max cross-section 150х150 mm

Max diameter 150 mm

Max length 3000 mm

- Max cross-section 150х150 mm

Max length 6000 mm

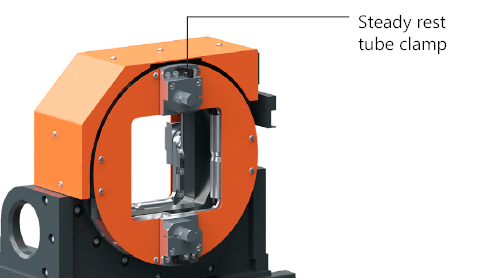

Steady rest to support the workpiece

Steady rest supports round tubes with different diameter.

- Max diameter 250 mm

Max length 3000 mm

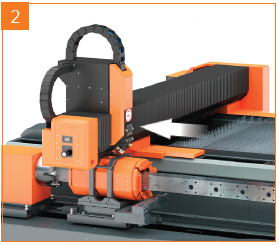

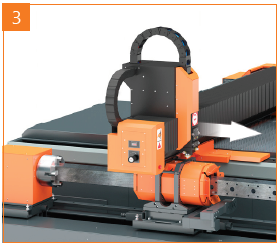

Laser head cuts the tube near the automatic steady rest which securely holds the workpiece preventing it from unwanted oscillations.

Having processed a part of tube the portal automatically holds the steady rest and moves it, providing some room for the next cutting area.

The portal quickly and efficiently moves the steady rest along the tube excluding dead spots while processing.

This solution leads to significant economy of time and expanded efficiency.