LaserClean

Laser cleaning machine

LaserClean – is a high-end, efficient laser cleaning machine outfitted with IPG fiber laser solution. It allows for removing rust, oil spots, paint, oxides, epoxy resins and other types of contamination from metal surfaces.

Applications

Modern laser cleaning machines are suitable for a wide range of applications in various industries:

- to remove rust of various density and thickness with no damage to metal surfaces;

- to treat welding seams of non-ferrous and ferrous metals in order to remove oxides and carbon deposits;

- to clean surfaces of a complex shape (parts of engines, transmission systems, mechanisms) from composite contamination (oil, ground, oil contamination);

- to clean parts of metal constructions from soil and paint before welding or painting;

- to remove grease, organic and soot contamination from the places where chemical or mechanical cleaning cannot be used (food industry, medicine, living quarters);

- to clean non-metallic products (plastic and rubber molds, stone and concrete surfaces, glass and ceramics);

- to clean objects of a complex shape with no mechanical and chemical impact on surfaces (restoration and renovation works);

- to remove composite contamination with just one laser cleaning machine both for small objects and large construction projects.

Non-contact cleaning technology of LaserClean - without any chemicals and surface and cover damage – enables to clean rough surfaces, hard-to-reach places and local zones.

Operating principle

Use of short pulses enables the laser to remove chemical compounds such as rust, dirt, paint coating, etc. leaving the surface clean and ready for further processing. Light pulses are so short that metal surface is not heated and deformed.

LaserClean Features

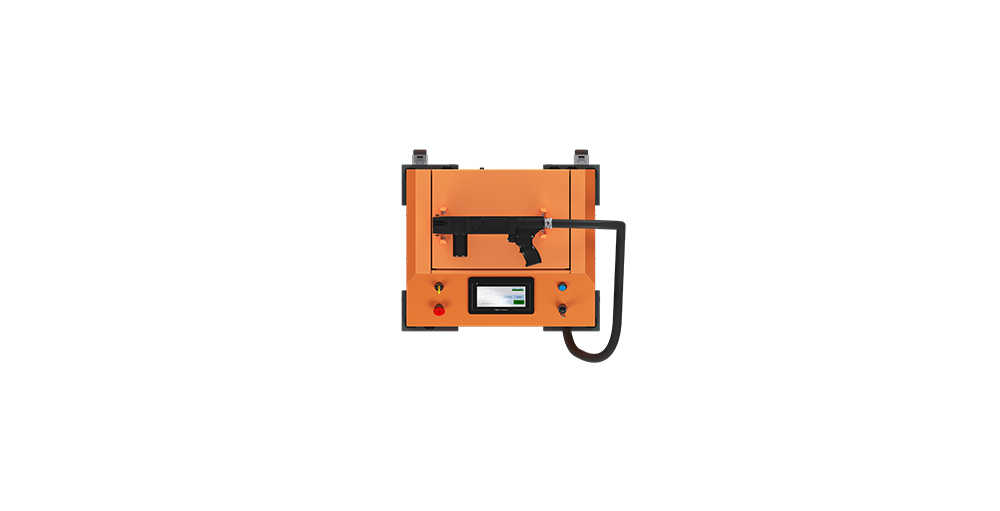

Non-contact cleaning

Mo mechanical impact or damage. No supplementary contamination, sand, dust, etc.

High accuracy processing

Galvanometric scanner as a part of laser cleaning gun ensures high accuracy of beam positioning. Depending on the technological goals an operator may adjust scanner beam length and width, and control percentage of laser power.

User-friendly operation

Our machine is easy to operate and does not require time-consuming personnel training. Just set several parameters and select laser power to readjust LaserClean. Save these parameters to use them afterwards as one of available operation modes.

No consumables

No consumables. Almost maintenance-free.

High mobility

Due to convenient design and small weight the machine may be easily moved around the production facilities and operated by one specialist only.

Main technical data

| General specifications | |

|---|---|

| Power | 500 W |

| Wave length | 1060 nm |

| Laser type | pulse |

| Capacity * | 12 m²/h |

| Cooling system | air |

| Operating temperature | 15-40°С |

| Maximum scan angle | ±15° |

| Horizontal deviation | 12 µrad |

| Vertical deviation | 8 µrad |

| Input aperture | 20 mm |

| Voltage | 220 V |

* - may differ depending on the material.

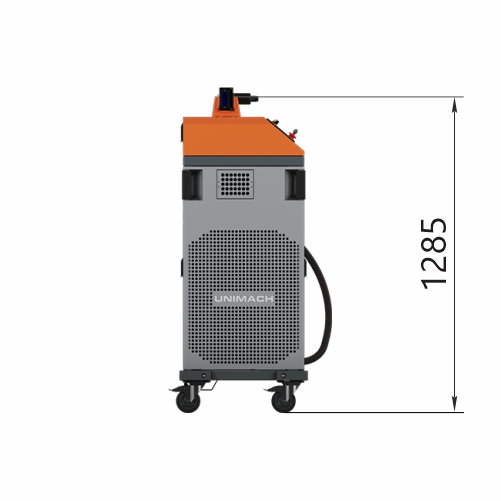

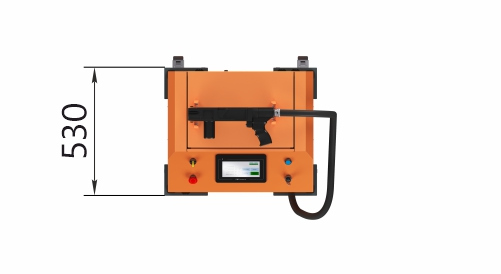

Overall dimensions

LaserClean overall dimensions