Machine control

Control

Control console is a separate dust-proof console equipped with an LCD to represent operating data. All controls and LEDs are located in front of the operator at the front panel. Such layout allows an operator to react within the shortest time and prevent any possible errors.

Control console UM-103

-

1. LCD monitorIndustrial 21" LCD monitor MV-2105.

-

2. Moving handleEnables an Operator to move the console easily along the cabinet protection

-

3. Wireless remote controlWireless remote control allows an Operator to carry out the most common operations from any place

-

4. Main controlsMain controls are located on the front panel of the control console to provide additional comfort

-

5. Emergency outage buttonEmergency outage button (shutdown).

-

6. KeyboardKeyboard with a mouse create conventional and comfortable working atmosphere.

-

1. IndicationIndication of completed programs

-

2. Free runningManual control of travel along axis

-

3. PalletControl of dual-pallet loading system

-

4. ControlControl over the equipment’s programs and functions

-

5. GasControl of gas supply, including automatic gas console

Control console UM-102

-

1. Wireless connectionAntenna to provide wireless connection with the remote control.

-

2. LCD monitorIndustrial 21" LCD monitor MV-2105.

-

3. UniCut SoftwareSimple and user-friendly software UniCut.

-

4. All controls are within reachMost frequently used controls are located on the front panel of the control console which makes it easier for an Operator to organize working process.

-

5. Secure control systemThe console also protects the cutting machine from unauthorized power on / off switching.

-

6. Pull-out keyboardKeyboard with a mouse create conventional and comfortable working atmosphere.

-

7. Storage drawersTo provide additional comfort the console has special drawers to store consumables or tools, and a holder for papers.

-

8. Barcode scanner Unimach Cordless ScannerQuick loading of cutting programs simplifies operation and is a great help for paper documentation.

-

9. IntegrationLAN port to integrate a machine to general manufacturing system is located on the back panel.

-

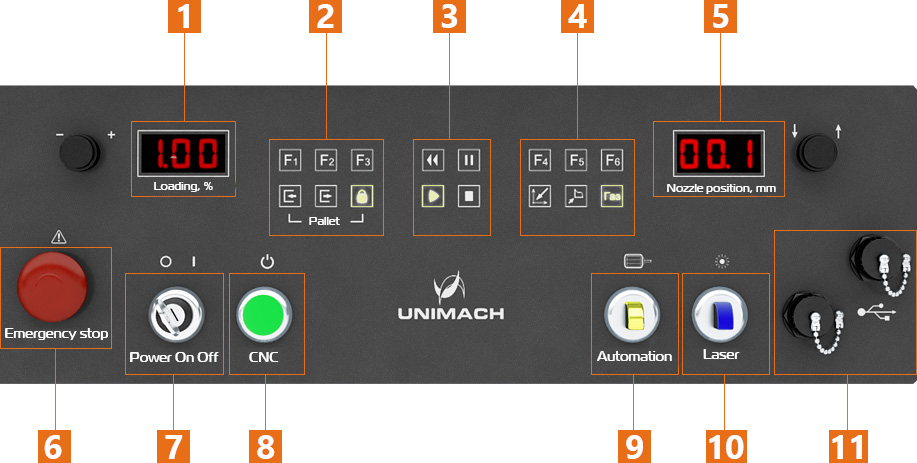

1. Loading indicatorLoading indicator represents the percentage between the current speed of workpieces processing and preset one. Use an encoder to set the percentage value (on the left).

-

2. Control buttonsButtons to control the pallet and functional

keys F1, F2, F3. -

3. Back travel buttons, etc.Back travel, pause, start and stop buttons.

-

4. Zero point travelTravel to machine and workpiece zero point, gas supply to the cutting area and functional keys F4, F5, F6.

-

5. Nozzle position indicatorNozzle position indicator shows the preset standoff between the nozzle and metal. Use the encoder to set the nozzle standoff (on the right).

-

6. Emergency stop buttonEmergency shutdown button.

-

7. Start key (switch)Turn the key to power the machine.

-

8. CNC buttonButton to switch on the control console.

-

9. Automation toggle switchToggle switch for automation.

-

10. Laser toggle switchLaser module toggle switch.

-

11. USB-portsUSB-ports to connect flash drives and download software and drawings.

Wireless remote control

Wireless remote control allows an Operator to do the most common operations from any place: start and stop, back travel along the contour, increasing / decreasing the focus length, upload speed change, machine and workpiece zero point. Operating distance — 10m. Time of autonomous operation: 96 hours. Battery charge is carried out from the USB.

Control panel of the shuttle table

Control panel allows for pallet changing in manual mode, start and stop operation in automatic mode. The panel is fastened on the side of the control console and installed in duplicate on the shuttle table.

Digital jam-resistant network UniNET

Machine’s electronic modules are integrated in the reliable digital jam-resistant network UniNET. CNC sends a signal to the connected peripheral equipment and controls its status.

UniNET lets an Operator control all peripheral equipment using united software of the control console, as well as carry out remote diagnostics of the system status. Auxiliary devices are connected directly to the network and do not require additional input / output ports on the CNC ensuring high scalability of the System.

Bluetooth barcode scanner Unimach Scanner

Bluetooth barcode Unimach Scanner increases speed and efficiency of operator’s work.

Quick loading of cutting programs simplifies operation and is a great help for paper documentation.

An Operator receives the printed task with barcodes, scans the barcodes and machine’s CNC automatically downloads proper cutting programs.

Therefore, an Operator simply presses the scanner’s button and do not waste time searching necessary files. This solution also excludes the human factor and reduces the possibility of choosing the wrong program.

The scanner is made of ABS, withstands multiple drops from 1.2 m height onto the concrete; IP rating is IP30, delivered with free software ScanMaster.