UniBend 1600-60

Press brake

Descirption

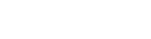

The new range of servo-electric press brakes UniBend is based on Unimach® ten year experience of designing and manufacturing laser cutting machines.

UniBend 1600-60 – is the most efficient solution for Large Enterprise which deals with detail production within 1600 mm range. Application of self-engineered servo drives enables us to reach bending speed of 20 mm/s significantly increasing performance and reducing production costs compared to conventional hydraulic press brakes.

High dynamics, reliability, reduced energy consumption (compared to hydraulic equipment) and minimal maintenance costs are on the plus side of servo-electric systems. Small dimensions paired with high efficiency enables this machine to be one of the best solutions for Small and Medium Enterprise.

Main features

Rigid О-frame machine bed

Robust O-frame bed construction ensures equal load distribution on the side frames thus removing the horizontal deflection and ensuring precise and predictable operations.

Unlike C-frame machines the side frames do not limit complicated details and back gauge allows for movements along the length.

We use self-engineered servo drives and drive systems

Servo drives for servomotors Unidrive series ensure the highest precision and easiest movement maintaining the maximum dynamics. Application of specially designed proprietary technologies to control servomotors results in precision and efficient operations with minimal offset within all speed and acceleration ranges.

Motion controllers UniMotion produced by Unimach® ensure mutual synchronization of servo drives. High speed ensures absence of tilting and unparalleled precision. Positioning accuracy of upper beam is ±0.01mm.

Belt drive

Controlled by servo drives, belt drive allows for uniform distribution of bending force along the upper beam thus providing minimal errors of bend angle along the whole workpiece.

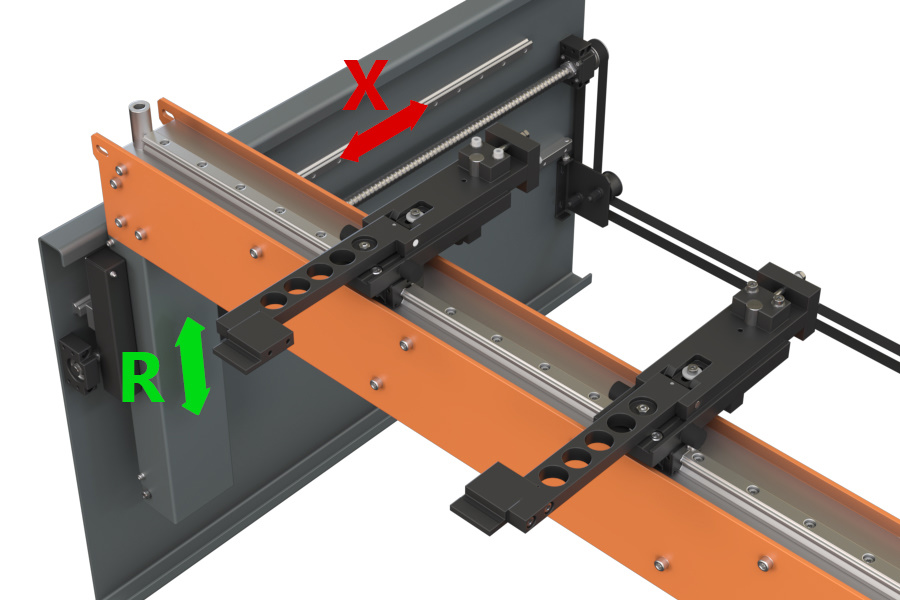

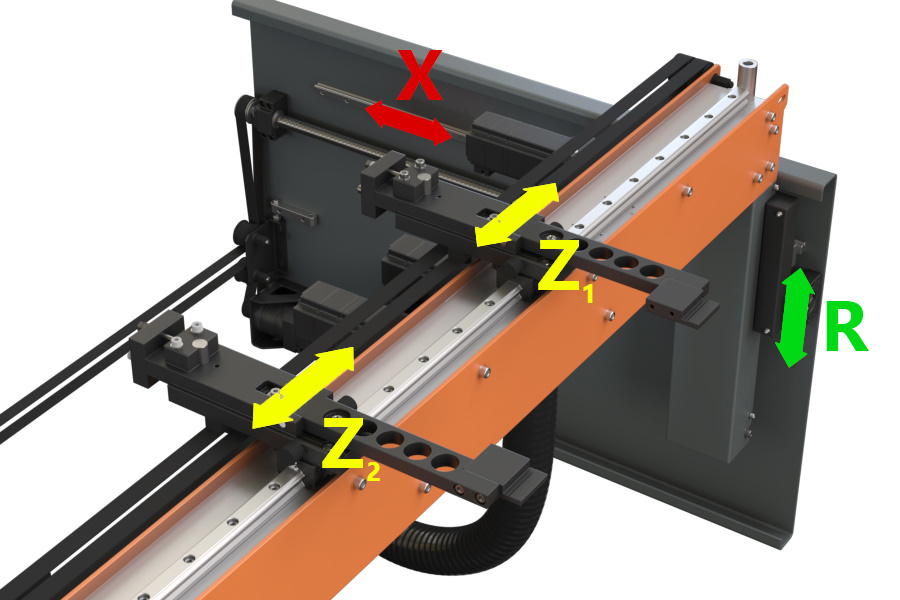

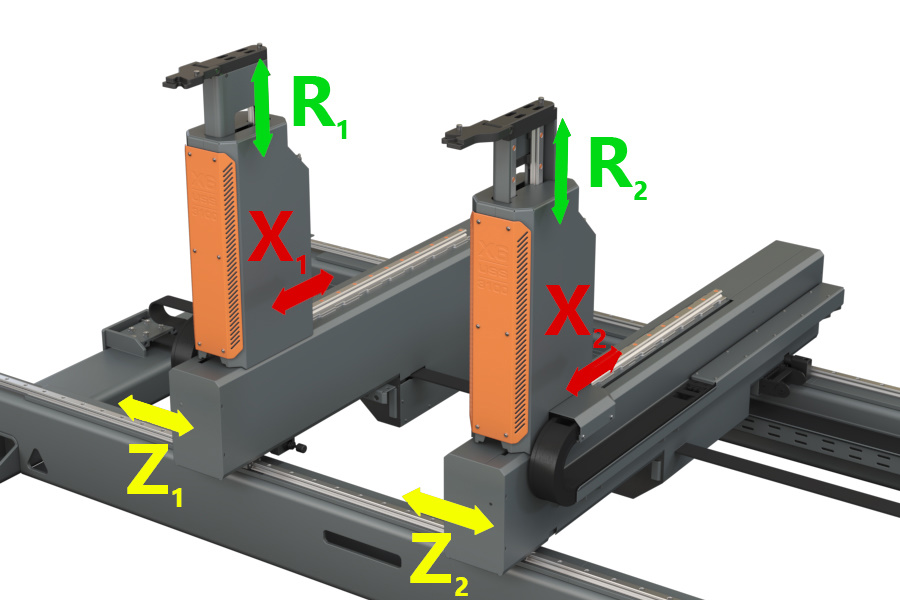

Automatic back gauge system

Depending on the volume and tasks of the manufacturing, automatic back gauge can have from 2 to 9 CNC-controlled axes thus ensuring the required level of equipment automation.

During operation life the press brake can be modernized by increasing a number of back gauge stops and adding CNC-controlled axes. Since the back gauge system is located on the separate frame any mechanical damage of the frame with bending tools is excluded.

Tooling system

Press brake UniBend is equipped with international well-known tooling system Amada-Promecam. Clamping of punches is carried out with the help of keybar adaptors enabling to align the tools in a perfectly straight row. Different types of adaptors ensure dies clamping.

High ergonomics

High ergonomics ensure low level of noise, convenient layout of control elements and both simple operation and maintenance. Safety components and guards protect an operator while both operation of the machine and its service.

Mounting system of control console allows for adjusting the workplace according to the workpiece positon on the lower beam. Using a tablet as a control module an operator can work in close proximity to the bending zone.

Main technical specifications

| General specifications | |

|---|---|

| Max. bending force, ton | 60 |

| Bending length, mm | 1600 |

| Machine bed | О-frame |

| Power supply voltage, V | 380 |

| Frequency, Hz | 50 |

| Max. weight, kg | 6500 |

| Speed and movements | |

|---|---|

| Approach speed (free run), mm/s | 120 |

| Approach speed (operating), mm/s | 20 |

| Return speed, mm/s | 120 |

| Max. stroke, mm | 300 |

| Daylight opening, mm | 600 |

| Accuracy parameters | |

|---|---|

| Upper beam positioning accuracy, mm | 0.01 |

| Back gauge positioning accuracy, mm | 0.05 |

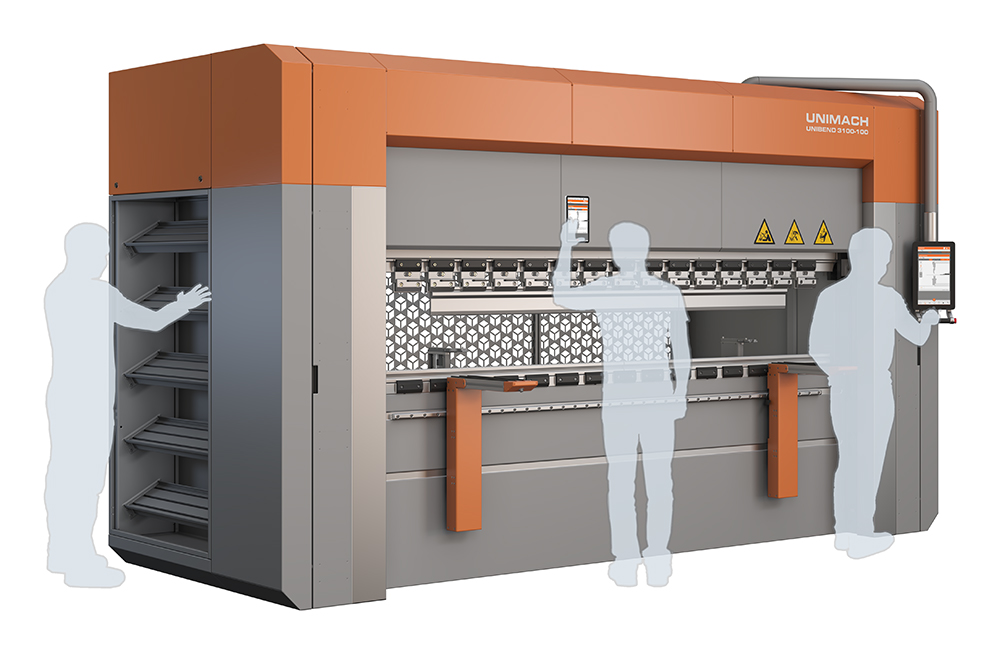

Overall dimensions

UniBend 1600-60 overall dimensions

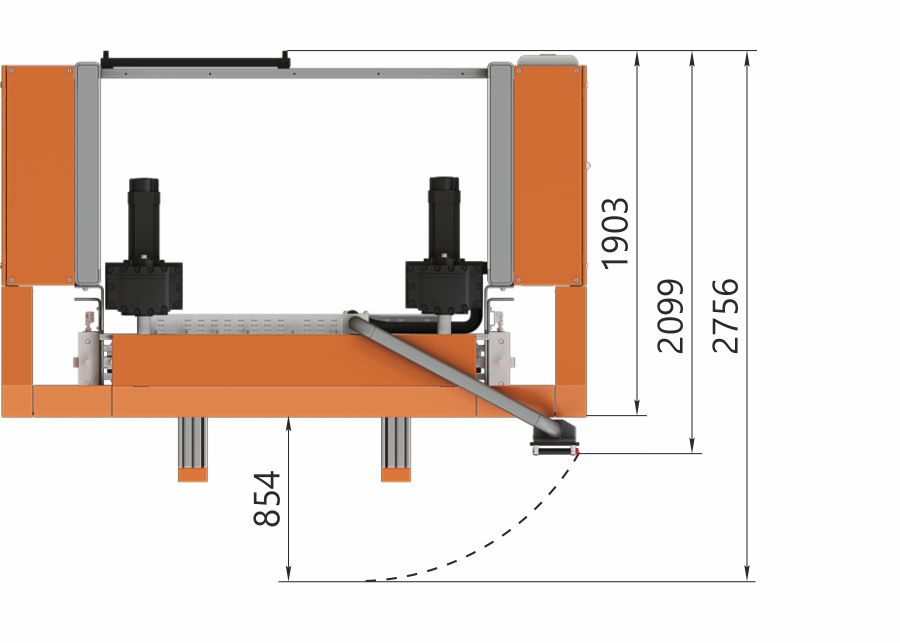

Control console

Press brake is controlled by the dust-proof control console equipped with a 15.6” touch panel. The console is mounted onto the frame with the help of rotating brackets enabling an operator to adjust it along the bending line and upwards for the most convenient position.

Touch panel ensures an easy integration of UniBend software into the production, significantly simplifying workpieces’ plotting as well as creating and editing bending programs.

Tablet

Additional control element – the tablet with UniBend software – has a magnet mounting which makes it possible to place the tablet anywhere on the upper beam.

It also ensures full control over machine operations in close proximity and visual monitoring of program and software commands execution.

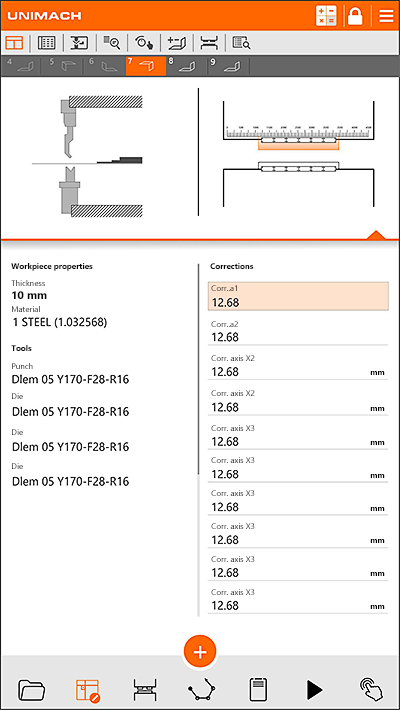

UniBend software

Developed by Unimach specialists our software has a user-friendly interface and operations control made-easy. Wide functionality allows for automatization of different press brake operations – from creating a bending program to machine adjustment under the workpiece size.

Sensor control makes an operator’s work even simpler and increases production efficiency. Menu icons correspond to every operation stage, their sequence repeats operator's actions allowing for easy and convenient use of software product.

Bending force is calculated automatically depending on the workpiece’s size and material. When the workpiece processing requires a sequence of several bends, the program automatically sets it up. An operator can correct it if necessary.

Standard equipment

- О-frame bolted bed

- Electromechanical drive

- UniBend Control CNC with a wireless communication module

- Foot pedal

- Clamping system Amada/Promecam for punches (European Style) with mechanical eccentric clamp (quick-lock)

- Clamping system Amada/Promecam for dies (European Style), mechanical

- Two-side lighting of working zone

- Automatic lubrication system

- Integrated tool storage system

- CNC unit is adjusted upwards with additional support arm

- Laser bend line

- Operating manual (electronic)

- Standard front support with additional arm

Additional equipment

- Automatic bending compensation system

- Safety system of working zone (planar laser)

- Safety system of working zone with automatic height adjustment (planar laser)

- Safety system of working zone (laser pointer)

- Safety system of working zone with automatic height adjustment (laser pointer)

- Front safety system (barrier photosensor)

- Access control system to back gauge zone

Back gauge movement system (proprietary development)

-

CNC controlled two back gauge along the axes X, R and manual movement along Z axis (2 axes)

-

CNC controlled two back gauge along the axes X, R, Z1, Z2 (4 axes)

-

CNC controlled two back gauge along the axes X1, X2, R1, R2, Z1, Z2 (6 axes)

- CNC controlled three back gauge along the axes X1, X2, X3, R1, R2, R3, Z1, Z2, Z3 (9 axes)

Front gauge

- Front gauge with servo drive based on standard support

- Front gauge with automatic workpiece support (servo drive and CNC controlled)

Tool clamping

- Quick-lock clamping system UniBend AirClamp Amada/Promecam (European Style)

- Clamping system WILA

- Clamping system Wilson

Other

- Additional foot pedal for two-person operation control

- Automatic thikness detection device

- Bend angle sensors

- Limited access to integrated tool storage system

- Left-side CNC

- Coating at any colour on request

- Three-section tool cabinet

- Five-section tool cabinet

- Control tablet with UniBend software

- LEDs of tool position

- Operator's work table

- Guides to install and dismantle tools from the side

- Additional back gauge fingers

- Movable control console